Background

The deliberate oxidation of white juice prior to fermentation is conducted to remove phenolics which can be perceived as bitter and astringent. The process also reduces the phenolic browning capacity of the resultant wine. Schneider (1998) indicated that in many instances the wines made using this process were in fact rated higher than wines made using conventional juice handling methods.

If grape must is not protected by sulfur dioxide, then naturally occurring enzymes such as tyrosinase commence activity and oxidise the phenolics present, turning them brown and precipitating them out. This process can be forced or encouraged by incorporating air or oxygen in the unsulfited juice prior to fermentation, making the resultant juice and wine less susceptible to phenolic browning. Hyperoxidised juice becomes very dark in colour; however, it generally produces lighter-coloured wines and wines that are less susceptible to oxidation compared to those produced using conventional juice handling methods (Gawel et al. 2008, Schneider 1998).

Practical and logistical considerations

There are a few different ways to incorporate oxygen at the juice stage, as summarised by Schneider (1998):

- Must is pumped straight from the press tray to a settling tank while oxygen is added via a diffuser on the transfer hose.

- Must is pumped and mixed in one tank while oxygen is added via a diffuser on the transfer hose.

- A diffuser is submerged in a tank and controlled amounts of oxygen are added to must using a flow meter.

- If flotation is used to remove suspended solids, then instead of using nitrogen for separation, oxygen or air can be used.

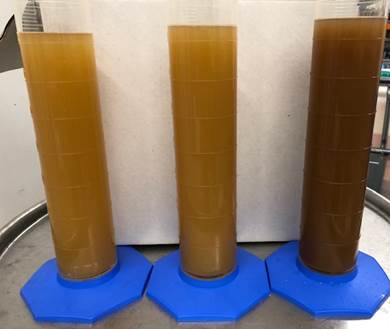

Figure 1. Varying juice solids content in Chardonnay juice. Left: 3% solids (532 NTU); middle: 4.5% solids (975 NTU); right: 6% ‘full solids’ (1,490 NTU).

Oxygen is the preferred gas for hyperoxidation; however, air can also be used and in some instances might be more readily available in a winery. If air is used, addition times need to be adjusted to account for the lower concentration of oxygen in air (21% oxygen). If air is sourced from a compressor, this needs to have checks in place to ensure volatiles from oils and lubricants do not contaminate the juice.

When performing hyperoxidation, the must is typically unsulfited. The effects of must temperature during hyperoxidiation have not been specifically studied; however, work by Hernanz et al. (2007) indicated that different types of phenolic compounds vary in their extraction dynamics with both time and temperature.

Foaming can be a problem when sparging and this should be taken into account when considering tank volume and ensuring sufficient ullage space is available.

Potential risks

In wet seasons when there is the risk of Botrytis being present in harvested fruit, oxidation of phenolics can be much more aggressive due to the presence of laccase which is a fungal enzyme associated with Botrytis infection. This enzyme has some resistance to sulfur dioxide and has a much greater capacity to oxidise a wider range of phenolic compounds in white juice. Hyperoxidation is not recommended in seasons when there is Botrytis present. An AWRI fact sheet is available with guidance on how to manage Botrytis-infected fruit.

It is well known that texture plays an important part in white wine style and that phenolics make a key contribution to the texture of white wines, so understanding how to modify the phenolic content of juice is important in white winemaking. Gawel et al. (2014) reported that pH combined with phenolic content contribute to perceived viscosity, and that juice extraction techniques such as hyperoxidation that decrease the phenolic content of juice can lead to wines with perceived lower viscosity and therefore less body.

Additional resources

Final report for Wine Australia – Identification of the major drivers of ‘phenolic’ taste in white wines – 8 February 2012.

Gawel, R., Day, M., Van Sluyter, S.C., Holt, H., Waters, E.J., Smith, P.A. 2014. White wine taste and mouthfeel as affected by juice extraction and processing. J. Agric. Food Chem. 62(41): 10008-10014.

Hernanz, D., Recamales, A.F., Gonzalez-Miret, M.L., Gomez-Miguez, M.J., Vicario, I.M., Heredia, F.J. 2007. Phenolic composition of white wines with a prefermentative maceration at experimental and industrial scale. J. Food Eng. 80(1) : 327-335.

Schneider, V. 1998. Must hyperoxidation: a review. Am. J. Enol. Vitic. 49(1): 65-73.