Background

Prior to fermentation, white grapes are pressed to extract the juice. The juice is cloudy due to presence of various solid compounds present in the skins and pulp, and pectinase enzymes are often used to help clarify the juice and settle out the solids. Grape solids consist of about 70% polysaccharides and 8% lipids, with the remaining material comprising mostly minerals, pectin, about 2.5% nitrogen and phenolic compounds.

Higher concentrations of grape solids provide yeast nutrients, particularly lipids and nitrogen, and consequently fermentations containing a greater proportion of solids experience faster and more complete fermentation and are less likely to become sluggish or stuck and have a faster rate of malolactic fermentation. However, while in controlled studies more rapid and complete fermentation results in wines with lower volatile acidity and acetaldehyde, higher grape solids have also been shown to produce wines with lower concentrations of esters, and higher concentrations of volatile sulfur compounds and higher alcohols, resulting in subdued varietal character. With modern winemaking equipment, winemakers have a choice regarding the quantity of grape solids to allow in the juice before fermentation commences. This ranges from using gentle handling of hand-harvested whole bunches with membrane pressing to achieve very low turbidity juice, which might be used Riesling or Sauvignon Blanc, to crushing and destemming, settling the juice for a short period, and then racking all but the heaviest lees to produce very high turbidity juice, as might be used for some Chardonnay wines. Getting the balance right is an important decision, because the level of solids directly affects fermentation performance and wine sensory properties.

Practical considerations and helpful hints

There are no standardised methods to objectively classify juice solids, or to quantify the ideal level for a particular wine; therefore, winemaker experience is important. The quantity and characteristics of the solids varies markedly between juices, depending on the physical characteristics of the grapes and, very importantly, the equipment and processes used for juice extraction.

The quantity of solids is most commonly expressed as NTUs (nephelometric turbidity units) with total wet or dry suspended solids, or percentage solids, also used. In a practical sense, NTU is the most useful way to assess, express and compare the relative quantity of solids in individual juices.

Is there an ideal NTU? One study (Nicolini et al. 2011) recommended NTUs of between 50 and 150 to ensure that yeast had access to sufficient lipids. However, it should be noted that with lower turbidity juice, addition of oxygen at the end of the yeast growth phase can compensate for lack of lipids in the juice, with the yeast able to use the oxygen to synthesise lipids. In another study, juices of three white varieties were fermented at six turbidities ranging from 15 to 350, with a turbidity of 100 NTU considered the ‘best compromise’ to maximise fruit aromas while avoiding either sluggish fermentations seen with lower turbidity, or ‘reductive’ sensory characters when the turbidity was higher.

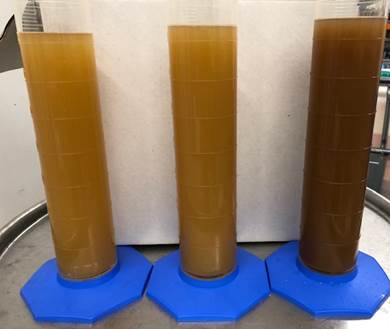

Examples of three solids levels are shown in Figure 1, representing three treatments in the trial:

- ‘whole bunch pressed control’ with 3% ‘light and fluffy’ solids added back to the juice

- ‘whole bunch pressed partial solids’ with 4.5% ‘light and fluffy’ solids added back to the juice

- ‘whole bunch pressed full solids’ with all solids added back to the juice

Figure 1. Varying juice solids content in Chardonnay juice. Left: 3% solids (532 NTU); middle: 4.5% solids (975 NTU); right: 6% ‘full solids’ (1,490 NTU).

Potential risks

Most of the polyphenol oxidase enzymes which promote juice browning in the presence of oxygen, are found in the grape skin, and therefore high-solids juices may be more susceptible to oxidation. In addition, the concentration of any vineyard-derived elemental sulfur in juice will also increase with increasing solids content, with that sulfur having potential to contribute to the formation of ‘reductive’ characters in wine. However, if managed correctly, the inclusion of a greater concentration of solids can facilitate the production of the ‘struck flint’ character prized in some Chardonnay wines.

Resources

Alexandre, H., Nguyen van Long, T., Feuillat, M., Charpentier, C. 1994. Contribution à l’étude des bourbes: Influences sur la fermentescibitédes moûts. (Contribution to the study of juice lees: Influences on the fermentability of musts). Rev. Fr Œnol. 146: 11-20.

Casalta, E., Vernhet, A., Sablayrolles, J-M, Tesière, C., Salmon, J-M. 2016. Review: Characterization and role of grape solids during alcoholic fermentation under enological conditions. Am. J. Enol. Vitic. 67(2): 133-138.

Gawel, R., Day, M., Schulkin, A., Smith, P. 2015. Murky winemaking: How juice solids affect the macromolecular composition and mouthfeel of white wine. Wine Vitic. J. 30(6): 18-22.

Godden. P. 2019 Ask the AWRI. Grape solids in white winemaking. Aust. N.Z. Grapegrower Winemaker (671): 73-74.

Nicolini, G., Moser, S., Román, T., Mazzi, E., Larcher, R. 2011. Effect of turbidity on fermentative volatile compounds in white wines. Vitis 50(3): 131-135.