Investigation of grape and wine production practices

60th anniversary review papers now in print

New smoke taint resources available

Grape samples needed for smoke taint background data

Getting predicted alcohol right – juice samples needed

AWITC registrations opening soon

Order the latest AWRI staff publications online

Investigation of grape and wine production practices |

|

|

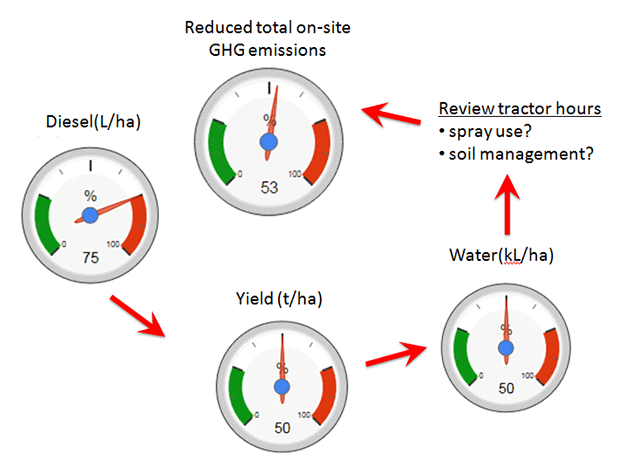

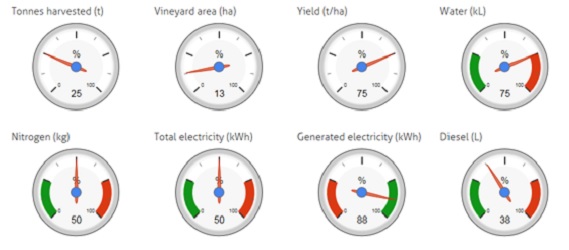

How common are different winery methods for pressing and clarification? Which different yeasts are being used by Australian winemakers? What are the most popular lab methods for assessing heat and cold stability? How widespread is cane versus spur pruning? How common are multi-row sprayers of different sizes and spray recovery units? For these and numerous other aspects of Australian grape and wine production there is limited data available on the prevalence of different practices and how they are changing with time.To address this gap, the AWRI is establishing a survey of Australian grape and wine production practices to be performed for the first time in 2016. The survey may be repeated at a later date to give a picture of changing practices over time.

The survey will provide aggregate anonymous data on the prevalence of different production practices. It will help inform R&D efforts by the AWRI and other research organisations, allow producers to compare their practices with regional and national norms, promote discussion on the different techniques available and provide a historical record. The survey questions are currently being developed, with the final survey planned for July and August 2016. Site visits will then follow to explore the reasoning behind different choices. If there are questions or topics relating to Australian grape and wine production that you think should be included in the study, please email simon.nordestgaard@awri.com.au. |

New AWRI website launched |

|

|

The AWRI launched a brand new look for https://www.awri.com.au/. Underneath the fresh design there is significant new content on AWRI research projects, a refresh of the popular AWRI helpdesk resources, updated fact sheets and lots of other changes. Have a look around the new site, and contact the Information Services team if you have any comments or questions. |

60th anniversary review papers now in print |

|

|

The special issue of the Australian Journal of Grape and Wine Research published as part of the AWRI’s 60th anniversary celebrations rolled off the printing press in late December 2015. The issue contains 18 review articles authored by AWRI staff on topics in viticulture, sensory science, wine chemistry and microbiology. The full list of article titles is available here. AJGWR subscribers will already have received their copy in the mail and can also access the review articles online. Non-subscribers are welcome to visit the AWRI library to read a hard copy of the special issue or browse through it on one of the library computers. Alternatively, requests for copies of specific review articles can be made by contacting AWRI library staff. |

New smoke taint resources availableThe Bureau of Meteorology has indicated that the 2015/2016 El Niño event currently influencing Australia’s weather is one of the top three strongest of the past 50 years. The potential effects of El Niño on Australia include warmer, more extreme temperatures and increased fire danger. This makes the 2016 vintage a high risk one with respect to bushfires and the associated possibility of smoke taint. With this in mind, the AWRI has recently put together two new smoke taint fact sheets to help inform grapegrowers and winemakers. One discusses the entry of smoke-related compounds into grapes, as well as vineyard risk factors, while the other looks at possible options for managing smoke-exposed fruit. The AWRI Commercial Services fact sheet about smoke taint analysis has also been recently updated. Other resources to help grapegrowers and winemakers with concerns about possible smoke contamination are available on the AWRI’s smoke taint webpage. For further information or assistance, please contact the AWRI helpdesk on helpdesk@awri.com.au or 08 8313 6600. |

|

Grape samples needed for smoke taint background dataDid you know that the compounds found in smoke-tainted grapes are also found in grapes that have not been exposed to smoke? The AWRI has a database of these ‘background levels’ that is used when assessing the risk of smoke taint in grapes that have been exposed to smoke. This allows a simple ‘traffic light’ indication of risk to be provided. The current database only covers five grape varieties, so an expansion is planned for this vintage. To make this happen, the AWRI is seeking 2 kg samples of Sauvignon Blanc, Pinot Gris, Semillon, Merlot and Grenache grapes that have not been exposed to smoke. The samples will need to be frozen once picked and then transported to the AWRI post-vintage. The AWRI will organise and pay for transport of samples to the AWRI and assist with quarantine requirements by supplying the relevant forms. Can you help out? Please follow this link and provide your details. https://www.surveymonkey.com/r/QDBJN6J For any extra information, please contact the AWRI helpdesk team on helpdesk@awri.com.au or 08 8313 6600. |

|

Getting predicted alcohol right – juice samples neededAccurately predicting the final alcohol of wine is one of the big challenges in wine production, with many winemakers relying on simple ‘rules of thumb’ that can be more than 1% (v/v) alcohol out. One of the keys to achieving more accurate alcohol predictions is a clear understanding of the actual fermentable sugar levels in juice and how they compare to total dissolved solids (TDS) levels measured as Brix or Baume. This vintage the AWRI is seeking juice samples to help in the development of a more accurate online calculator to predict final alcohol. Participants will be asked to provide frozen 50 mL juice samples along with their measured Brix and TA and then information on the fermentation characteristics used, the yeast type, and the final alcohol of the wine. The AWRI will be measuring the content of fermentable sugars (glucose and fructose) in the juice as well as quantifying the non-fermentable component of the TDS. The information will be collated and used to develop an online calculator for next vintage. To participate in the trial, or for more information, please contact Eric Wilkes on 08 8313 6600 or eric.wilkes@awri.com.au. |

|

AWITC registrations opening soon |

|

|

It’s now less than two weeks until registrations open for the 16th Australian Wine Industry Technical Conference on 8 February. The conference program is shaping up well, with a wide range of overseas and Australian speakers now confirmed. Details of the workshop program are also available, with 39 workshops to be held on Sunday 24 July and Wednesday 27 July 2016.

Poster abstract submissions remain open, and all submissions will be considered for inclusion in one of the ‘Fresh science’ conference sessions. Trade Exhibition sales are continuing to progress – further details about the exhibition are available on the AWITE website. To keep in touch with all things AWITC & TE, add your email address to the AWITC mailing list and follow the AWITC on twitter. |

Order the latest AWRI staff publications onlineAccessing the latest AWRI publications is easy. Visit the AWRI Publications web page to:

A full list of AWRI publications published since the last eNews is included below. 1753 Ward, S.C., Petrie, P.R., Johnson, T.E., Boss, P.K., Bastian, S.E.P. Unripe berries and petioles in Vitis Vinifera cv. Cabernet Sauvignon fermentations affect sensory and chemical profiles. Am. J. Enol. Vitic. 66 (4): 435-443; 2015. 1754 Hixson, J.L., Bindon, K.A., Smith, P.A. Evaluation of direct phloroglucinolysis and colorimetric depolymerization assays and their applicability for determining condensed tannins in grape marc. J. Agric. Food Chem. DOI: 10.1021/acs.jafc.5b04207: 31 p.; 2015. 1755 Krstic, M.R., Johnson, D.L., Herderich, M.J. Review of smoke taint in wine: smoke-derived volatile phenols and their glycosidic metabolites in grapes and vines as biomarkers for smoke exposure and their role in the sensory perception of smoke taint. Aust. J. Grape Wine Res. 21 (S1): 537-553; 2015. 1756 Smith, P.A., McRae, J.M., Bindon, K.A. Impact of winemaking practices on the concentration and composition of tannins in red wine. Aust. J. Grape Wine Res. 21 (S1): 601-614; 2015. 1757 Chambers, P.J., Borneman, A.R., Varela, C., Cordente, A.G., Bellon, J.R., Tran, T.M.T., Henschke, P.A., Curtin, C.D. Ongoing domestication of wine yeast: past, present and future. Aust. J. Grape Wine Res. 21 (S1): 642-650; 2015. 1758 Bekker, M.Z., Day, M.P., Holt, H., Wilkes, E., Smith, P.A. Effect of oxygen exposure during fermentation on volatile sulfur compounds in Shiraz wine and a comparison of strategies for remediation of reductive character. Aust. J. Grape Wine Res. DOI: 10.1111/ajgw.12172: 12 p.; 2015. 1759 Bartowsky, E.J., Costello, P.J., Chambers, P.J. Emerging trends in the application of malolactic fermentation. Aust. J. Grape Wine Res. 21 (S1): 663-669; 2015. 1760 Higginson, E.G., Lloyd, N.D.R., Kravchuk, O., Ford, C.M., Thomas, M.R. A high-throughput UHPLC MS/MS method for evaluation of tartaric and malic acid concentration in individual grapevine berries. Aust. J. Grape Wine Res. DOI: 10.1111/ajgw.12170: 8 p.; 2015. 1761 Longbottom, M. Ask the AWRI: Nitrous oxide and viticulture. Aust. N.Z. Grapegrower Winemaker (621): 42-43; 2015. 1762 Scrimgeour, N. Ferment sensor technologies put through their paces. Aust. N.Z. Grapegrower Winemaker (621): 68, 70, 72-74; 2015. 1763 Coulter, A. Ask the AWRI: Spoilage due to lactic acid bacteria. Aust. N.Z. Grapegrower Winemaker (622): 76-77; 2015. 1764 Coulter, A.D., Holdstock, M.G., Cowey, G.D., Simos, C.A., Smith, P.A., Wilkes, E.N. Potassium bitartrate crystallisation in wine and its inhibition. Aust. J. Grape Wine Res. 21 (S1): 627-641; 2015. 1765 Mierczynska-Vasilev, A., Smith, P.A. Current state of knowledge and challenges in wine clarification. Aust. J. Grape Wine Res. 21 (S1): 615-626; 2015. 1766 Curtin, C., Varela, C., Borneman, A. Harnessing improved understanding of Brettanomyces bruxellensis biology to mitigate the risk of wine spoilage. Aust. J. Grape Wine Res. 21 (S1): 680-692; 2015. 1767 Schmidt, S.A., Henschke, P.A. Production, reactivation and nutrient requirements of active dried yeast in winemaking: theory and practice. Aust. J. Grape Wine Res. 21 (S1): 651-662; 2015. 1768 Godden, P., Wilkes, E., Johnson, D. Trends in the composition of Australian wine 1984-2014. Aust. J. Grape Wine Res. 21 (S1): 741-753; 2015. 1769 Varela, C., Dry, P.R., Kutyna, D.R., Francis, I.L., Henschke, P.A., Curtin, C.D., Chambers, P.J. Strategies for reducing alcohol concentration in wine. Aust. J. Grape Wine Res. 21 (S1): 670-679; 2015. 1770 Longbottom, M.L., Petrie, P.R. Role of vineyard practices in generating and mitigating greenhouse gas emissions. Aust. J. Grape Wine Res. 21 (S1): 522-536; 2015. 1771 Herderich, M., Barter, S., Black, C.A., Bramley, R., Capone, D., Dry, P., Siebert, T., Zhang, P. Terroir effects on grape and wine aroma compounds. Ebeler, S.B., Sacks, G., Vidal, S., Winterhalter, P. (eds.) Advances in wine research. Washington, D.C: American Chemical Society: 131–146; 2015. (ACS Symposium series; 1203). 1772 Longbottom, M. A successful seminar and awards night. Wine Vitic. J. 30 (6): p. 10; 2015. 1773 Gawel, R., Day, M., Schulkin, A., Smith, P. Murky winemaking: How juice solids affect the macromolecular composition and mouthfeel of white wine. Wine Vitic. J. 30 (6): 18-22; 2015. 1774 Smith, P., Schulkin, A., Kassara, S., Barter, S., Solomon, M., Cynkar, W., Capone, D., Francis, L., Bindon, K., Johnson, D. Applying the latest understanding of grape composition. Wine Vitic. J. 30 (6): 33-36, 38; 2015. 1775 Dry, P. Friulano. Wine Vitic. J. 30 (6): p. 54; 2015. 1777 Johnson, D. 2015 Report: Implementation and execution. Aust. N.Z. Grapegrower Winemaker (623): 67-70; 2015. 1778 Lloyd, N., Johnson, D.L., Herderich, M.J. Metabolomics approaches for resolving and harnessing chemical diversity in grapes., yeast and wine. Aust. J. Grape Wine Res. 21 (S1): 723-740; 2015. 1779 Johnson, D.L., Rose, L.E. Foreword to the special edition of the Australian Journal of Grape and Wine Research celebrating the 60th anniversary of The Australian Wine Research Institute. Aust. J. Grape Wine Res. 21 (S1): p. 521; 2015. 1780 Black, C.A., Parker, M., Siebert, T.E., Capone, D.L., Francis, I.L. Terpenoids and their role in wine flavour: recent advances. Aust. J. Grape Wine Res. 21 (S1): 582-600; 2015. 1781 Day, M.P., Schmidt, S.A., Smith, P.A., Wilkes, E.N. Use and impact of oxygen during winemaking. Aust. J. Grape Wine Res. 21 (S1): 693-704; 2015. 1782 Smith, M.E., Bekker, M.Z., Smith, P.A., Wilkes, E.N. Sources of volatile sulfur compounds in wine. Aust. J. Grape Wine Res. 21 (S1): 705-712; 2015. 1783 Scrimgeour, N., Nordestgaard, S., Lloyd, N.D.R., Wilkes, E.N. Exploring the effect of elevated storage temperature on wine composition. Aust. J. Grape Wine Res. 21 (S1): 713-722; 2015. 1784 Dry, P. Marzemino. Wine Vitic. J. 28 (4): p. 63; 2013. 1785 Bindon, K.A., Carew, A.L., Mierczynska-Vasilev, A., Kassara, S., Kerslake, F., Smith, P.A. Characterization of macromolecular complexes in red wine: composition, molecular mass distribution and particle size. Food Chem. 199: 838-846; 2016. 1786 Sparrow, A.M., Holt, H.E., Pearson, W., Dambergs, R.G., Close, D.C. Accentuated cut edges (ACE): effects of skin fragmentation on the composition and sensory attributes of Pinot noir wines. Am. J. Enol. Vitic. DOI: 10.5344/ajev.2015.15094: 32 p.; 2016. 1787 Holdstock, M. Ask the AWRI: All things analysis. Aust. N.Z. Grapegrower Winemaker (624): 52-53; 2016. 1788 Wilkes, E. Baume to alcohol: It’s only an approximation. Aust. N.Z. Grapegrower Winemaker (624): 59-61; 2016. 1789 Nordestgaard, S. SIMEI 2015 – Wine, olive oil and decanters. Aust. N.Z. Grapegrower Winemaker (624): 66-68; 2016. |

|

AcknowledgementThe AWRI acknowledges support from Australia’s grapegrowers and winemakers through their investment body, Wine Australia, with matching funds from the Australian Government. The AWRI is a member of the Wine Innovation Cluster in Adelaide, South Australia. |

|