Pre-vintage reminder on Brett avoidance and control

Making the most of your smart phone or tablet in the vineyard

Refrigeration and wastewater workshops

Encouraging Chinese consumers to choose Australian wines

Nobel Prize winner to join the AWRI Board

Partnerships bring new opportunities

Well-deserved recognition for Mardi Longbottom

AWRI Annual Report available online

Recent literature

Pre-vintage reminder on Brett avoidance and control

With another vintage just around the corner (or already commenced in some of the warmer regions) it is a good time to brush up on the winemaking practices that can help to avoid Brettanomyces spoilage. As harvest is such a busy time of year and often involves new staff members, simple procedures can be overlooked in the rush. The AWRI has put together a list of tips that will help you stay on top of Brett prevention.

- Sulfur dioxide is Brett’s worst enemy and the sooner you can make additions to harvested fruit, the better. Machine harvested fruit is particularly in need of protection, so consider a 100 g/tonne addition of potassium metabisulfite (PMS) to bins.

- High pH favours Brett growth so if you know that your must is likely to have high pH, make an acid addition at the crusher. As soon as you know the pH of the homogenised must (make sure the sample is representative) adjust the pH if necessary. Red musts should be adjusted to below pH 3.4 whilst aiming for a titratable acidity (TA) of about 7.5 – 8.0 g/L. However, if the desirable TA cannot be achieved, then the must should be adjusted to pH 3.4 or below regardless of the amount of tartaric acid required to do so. Note that a large amount of the acid added will drop out later as potassium bitartrate (KHT), resulting in a decrease in the TA in the finished wine.

- During fermentation, potassium ions are leached from grape skins, resulting in a pH rise. It is recommended, therefore, that pH be measured during fermentation on skins and additions should be made to maintain the pH in the range 3.4 – 3.5. If the pH of the resulting wine is greater than 3.6, then precipitation of KHT will result in an increase in pH, which is undesirable because high pH favours Brett growth. If the wine pH is less than 3.6, then precipitation of KHT results in a decrease in pH, which is more desirable.

- Ensure that all winery and vineyard equipment such as grape bins are sanitised regularly and that wine hoses are drained of cleaning water. Water combined with sugar is an ideal breeding ground for a host of spoilage microorganisms.

- Ensure red ferments are healthy with a sufficient yeast cell population to complete ferment; Brett growth is highly favoured in the presence of residual sugar. Keep ferments warm towards the end, particularly once off skins, and check residual sugar levels, especially if going straight to barrel.

- Barrels can be a major source of contamination; if you have any suspect barrels you can get them tested through the AWRI’s Commercial Services https://www.awri.com.au/commercial_services/analytical_services/analyses/4ep-4eg/.

- Whilst various forms of barrel cleaning are available, if you have a history of Brettanomyces contamination the recommended treatment is to fill barrels with hot water at 85°C for fifteen minutes or until the exterior of the barrel is hot to touch. Take the time to check that your hot water thermostat is accurate pre-vintage and make sure staff are aware of the OH&S issues associated with working with hot water.

- Malolactic fermentation (MLF) is a critical period for avoiding Brett contamination and growth. Ensure that pH levels never get higher than 3.6 by adjusting early (see points 2 and 3), keep barrels topped and ensure that barrels are sulfured as soon as you know MLF is complete. A large SO2 addition is better than multiple small ones, so consider an 80 mg/L addition post MLF.

- If you take one action this vintage to control Brett, do this: add a column for molecular SO2 (MSO2) to your lab analysis sheet. Molecular sulfur dioxide is determined by the relationship between pH and free SO2, and it is recommended to maintain levels above 0.6 mg/L. To calculate MSO2, you can use the AWRI’s online calculator https://www.awri.com.au/industry_support/winemaking_resources/calculators/molecular-sulfur-dioxide/ or the AWRI winemaking calculators app https://www.awri.com.au/industry_support/winemaking_resources/winemaking-calculators-app/.

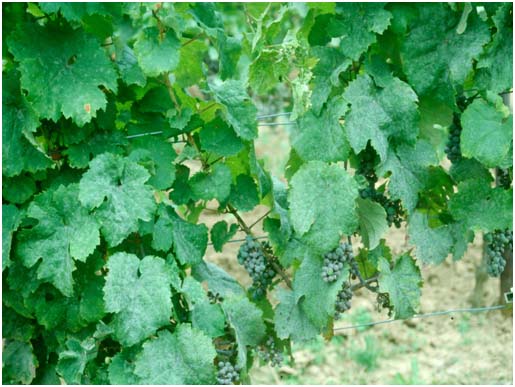

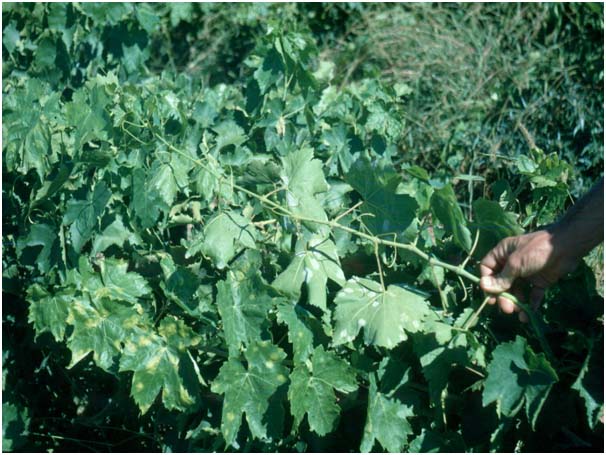

Making the most of your smart phone or tablet in the vineyard

Smart phones and tablets have rapidly transformed the way in which data and information can be obtained, collected and stored. With the increasing access that grapegrowers and viticulturists have to these tools, there are substantial resources and digital technologies available to increase productivity and efficiency and improve vineyard management.

The AWRI has developed a practical, hands-on workshop to be delivered during 2014 to assist grapegrowers in integrating smart phones and tablets into the management of their businesses. The workshop will be launched in the Barossa Valley and McLaren Vale next week.

Topics covered will include internet access, different technology platforms, data plans and coverage, tools to assist in working remotely, accessories, mobile security, apps relevant to vineyard management and viticultural businesses, and social media.

Dates and venues for the two launch workshops are :

15 January 2014, 9am-1pm – Barossa Weintal Resort, Tanunda SA

16 January 2014, 9am-1pm – McLaren Vale Visitor Centre, McLaren Vale SA

To book a place, please contact Paula Edwards on 08 8323 0056 or paula.edwards@winegrapes.com.au.

For more information, or if you think the growers in your region could benefit from attending this workshop, please contact Peter Godden on peter.godden@awri.com.au or 08 8313 6600.

Refrigeration and wastewater workshops

AWRI Commercial Services engineers are running two winery operations workshops in WA next week. The one-day workshops will focus on winery refrigeration and wastewater – key areas for reducing costs and improving environmental impact. The workshops will take place at the following dates and locations:

14 January, 9am-4.30pm – Faber Vineyard, Baskerville WA

16 January, 9am – 4.30pm – Cape Mentelle, Margaret River WA

To register, contact Jodie Panel at Wines of Western Australia by fax: 08 9284 4211, phone: 08 9284 3355 or email: reception@winewa.asn.au

If you are interested in bringing a similar workshop to your region, please contact Eric Wilkes, Group Manager – Commercial Services on eric.wilkes@awri.com.au or 08 8313 6600.

Encouraging Chinese consumers to choose Australian wines

Messages about the good quality and taste of Australian wines are most effective in encouraging Chinese consumers to choose Australian wine, compared to other communications about Australia. When consumers in China were told in a magazine article that Chinese people in general prefer the taste of Australian wines, their choice of Australian wine increased significantly over French, Italian and Chinese wines. This key result comes from a collaborative project investigating the impact of different messages about Australia on the wine purchasing behaviour of consumers in China

Apart from the taste message, the next most influential message in encouraging choice of Australian wines was one highlighting Australia’s clean unpolluted environment. An article about Australia’s great beaches and tourist attractions was the least effective, although there was still a positive response compared to a control group. Wine ratings and shelf communication were also shown to be very important for Chinese consumers when choosing a wine to buy.

The project was completed in August with over 1600 Chinese consumers of imported red wine exposed to five different messages about Australia in the form of advertorial-type articles, after which they made purchase selections in a simulated retail situation. The project was conducted by the AWRI sensory team, working with a group of wine industry advisors, as well as Larry Lockshin at UniSA and Simone Mueller-Loose at the University of Aarhus.

The second phase of this project is currently underway and involves consumers tasting Australian, Chinese and French wines under both blind and informed conditions. The results will be presented in another webinar by Patricia in February – watch this space!

Nobel Prize winner to join the AWRI Board

Winemaker and Nobel Prize-winning astronomer, Prof. Brian P. Schmidt, AC, FAA, FRS will join the AWRI Board as a special qualifications director in February 2014.

Brian is a Distinguished Professor at the Australian National University Research School of Astronomy and Astrophysics. He shared the 2011 Nobel Prize for Physics with Saul Perlmutter and Adam G. Riess for the discovery of the accelerating expansion of the Universe. He was elected Fellow of the Royal Society in 2012 and appointed a Companion (AC) in the General Division of the Order of Australia in 2013. He is a non-executive Director of Astronomy Australia, a member of the Council of the Australian Academy of Science and serves on three Government advisory boards.

Brian is also the owner operator of Maipenrai Vineyard and Winery in the Canberra District – a small producer of high quality Pinot Noir wines.

Brian gave the opening address at the 15th AWITC where he spoke about the importance of creativity and risk-taking in science.

Partnerships bring new opportunities

The AWRI has recently confirmed its involvement in three partnerships, one Australian and two international, that will bring benefits to the Australian wine industry.

The first is a partnership with the Ramaciotti Centre for Genomics at the University of New South Wales which will apply metagenomics techniques to map the composition of wild ferments. This work aims to shed light on the contribution of microbes to wine regional character. Knowledge gained will allow winemakers to take full advantage of local wild yeast and bacteria. It will also enable new yeast and bacteria strains to be developed, drawing on existing regional diversity and the AWRI microbial germplasm collection assembled over the past 50 years.

The second is an international alliance (known informally as the ‘BAG’ alliance) with the Institute of Vine and Wine Sciences (ISVV) (Bordeaux, France) and the Hochschule Geisenheim University (HGU) (Geisenheim, Germany). This partnership will involve cooperation on research areas of mutual interest, exchange of people, projects and information as well as the sharing of infrastructure and expertise across the grape and wine value chain. The Government of South Australia is supporting the new alliance through the Premier’s Research and Industry Fund.

Four areas of priority for collaboration have recently been identified for the BAG alliance:

- Adaptation to climate change

- Management of the spoilage yeast Brettanomyces

- Grapevine trunk diseases

- Consumer behaviour in China

Projects in these four areas will launch early in 2014.

The third partnership is a continuation of the AWRI’s successful collaboration with the Institute of Masters of Wine (IMW), under which the two organisations provide support to each other’s extension and education programs.

The AWRI hosted the IMW’s Australasian seminar in November, and gave a presentation on wine faults and taints to the MW students. Members of the IMW are likely to contribute to AWRI extension events over the next two years. The collaboration also allows the AWRI to access wines that are not available in Australia and import them for use in tasting programs, most recently the successful World Chardonnay and Pinot Noir tasting. In May 2014, Peter Godden will be presenting at the IMW’s 8th Symposium, in a session on the frontiers of wine research.

Well-deserved recognition for Mardi Longbottom

AWRI Viticulturist Mardi Longbottom has received recognition of a very successful 2013 with two awards. She has won a place in the Governor’s Leadership Foundation program for 2014, with a full scholarship provided by Primary Industries and Regions SA (PIRSA). Mardi was also the recipient of the 2013 AWRI Innovation award.

The Governor’s Leadership Foundation (GLF) program contributes to the prosperity of South Australia by inspiring South Australians with leadership potential through enhancing their self-awareness, emotional intelligence, problem solving analysis and strategic foresight ability. The 10-month program is delivered through a mix of:

- seminars;

- forums;

- field trips;

- individual coaching sessions; and

- group work.

The AWRI Innovation award is awarded annually, with a shortlist drawn up based on nominations and voting by AWRI staff, and the final winner chosen by a Board sub-committee. Mardi was recognised for her success in initiating and financing several extension activities of relevance to grapegrowers, adding to the AWRI’s existing service offering to winemakers.

AWRI Annual Report available online

The AWRI’s 2013 Annual Report is now available from the AWRI website. You can download a copy in pdf format or browse through an eBook version.

Recent literature

John Fornachon Memorial Library at the AWRI delivers journal articles and loans books to Australian grapegrowers and winemakers. Books can be searched and requested via the Library catalogue – or you can email the Library with your request. A list of recent AWRI publications follows.

- To order AWRI staff publications and articles from Technical Review please contact the Library

- Articles and books on specific topics can be searched for and ordered via the Library catalogue

- To request a Literature search on a specific topic contact the Library via email or telephone 08 8313 6600.

Recent AWRI staff publications

1569 Mangoni, A.A., Stockley, C.S., Woodman, R.J. Effects of red wine on established markers of arterial structure and function in human studies: current knowledge and future research directions. Expert Rev. Clin. Pharmacol. 6 (6): 613-625; 2013.

1570 Coulter, A. Ask the AWRI: Understanding the ABCs of CMCs in stabilisation. Aust. N.Z. Grapegrower Winemaker (598): p. 72; 2013.

1571 McRae, J.M., Kassara, S., Kennedy, J.A., Water, E.J., Smith, P.A. Effect of wine pH and bottle closure on tannins. J. Agric. Food Chem. 61 (47); 2013.

1572 Kidman, C.M., Mantilla, S.O., Dry, P.R., McCarthy, M.G., Collins, C. The effect of water stress on reproductive performance of Shiraz (Vitis Vinifera L.) grafted to rootstocks. Am. J. Enol. Vitic. doi: 10.5344/ajev.2013.13069; 2013.

1573 Jolly, N. P., Varela, C., Pretorius, I. S. Not your ordinary yeast: non- Saccharomyces yeasts in wine production uncovered. FEMS Yeast Res. doi:10.1111/1567-1364.12111; 2013.

1574 Longbottom, M. Greenhouse gas abatement in viticulture. Aust. N.Z. Grapegrower Winemaker (598): 35-38; 2013.

1575 Muhlack, R., Scrimgeour, N., Wilkes, E., Godden, P., Johnson, D. Optimising fermentation through simulation. Wine Viti. J. 28 (6): 38, 40-43; 2013.

1576 Dry, P. Schönburger. Wine Viti. J. 28 (6): p. 58; 2013.

1577 Viviers, M.Z., Smith, M.E., Wilkes, E., Smith, P. Effects of five metals on the evolution of Hydrogen sulphide, Methanethiol, and Dimethyl sulphide during anaerobic storage of Chardonnay and Shiraz wines. J. Agric. Food Chem. doi.org/10.1021/jf403422x: 12 p.; 2013.

1578 Johnson, D. Fascinating story to tell. Aust. N.Z. Grapegrower Winemaker (599): p. 30; 2013.

1579 Dry, P. If the grape fits then you can grow it. Aust. N.Z. Grapegrower Winemaker (599): p. 57; 2013.

1580 Muhlack, R., Forsyth, K., Scrimgeour, N., Godden, P. There’s gotta be a buck in those organic by-products. Aust. N.Z. Grapegrower Winemaker (599): 80-82; 2013.

1581 Johnson, D. 2013 Report: Planning for the future. Aust. N.Z. Grapegrower Winemaker (598): 81-84; 2013.

1582 Tran, T., Wilkes, E. How does CMC behave in NZ wines? NZ Winegrower (83): 67-69; 2013.

Disclaimer

The material contained in this publication is comment of a general nature only and is not and nor is it intended to be advice on any specific technical or professional matter. In that the effectiveness or accuracy of any technical or professional advice depends upon the particular circumstances of each case, neither the AWRI nor any individual author accepts any responsibility whatsoever for any acts or omissions resulting from reliance upon the content of any articles. Before acting on the basis of any material contained in this publication, we recommend that you consult appropriate technical/professional advisers.