Important regulatory changes for wine exported to China

Vintage 2014 – Half time report

Significant interest in low alcohol yeast

Closure benchmarking trial set to sparkle

Which paints cause taints?

Did you miss a webinar?

Two new fact sheets shed light on tannin measurement

Louisa Rose to chair the AWRI Board

Australian Wine Industry Technical Conference update

2006-2013 Final Report available online

Recent literature

Important regulatory changes for wine exported to China

On 27 February, Wine Australia released a warning to wine exporters regarding the increased scrutiny of manganese, iron and copper levels in wine by Chinese authorities. Maximum regulatory levels now being imposed by Chinese authorities are 2 mg/L for manganese, 1 mg/L for copper and 8 mg/L for iron. It is therefore recommended that all wine intended for export to China should undergo analysis to confirm that it complies with these limits. Excessive levels of copper and iron in wine have been shown to decrease the shelf life of wines and in some cases promote the formation of unpleasant sulfides, while manganese has a limited impact on wine chemistry. For all three metals there are no health concerns at these levels.

Analysis of these metals is available through reputable laboratories including AWRI Commercial Services For more information about manganese and other metals please contact winemakingservices@awri.com.au.

Vintage 2014 – Half time report

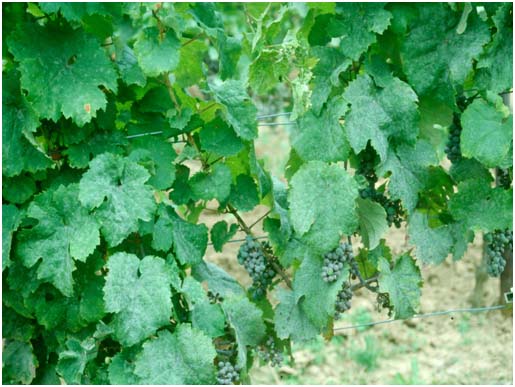

Vintage is well underway in most regions now, and so far it has been one influenced by extreme weather conditions, especially in south-eastern Australia. Heatwaves and record breaking daytime temperatures, followed by 100 mm of rain in some locations, have been experienced in the first part of the 2014 vintage. Smoke taint has been by far the biggest concern this vintage and represents nearly 25% of the vintage-related calls received by the AWRI’s helpdesk so far.

As reported previously (eNews November 2013) most wine-grape varieties are highly sensitive to smoke taint from seven days post-veraison to harvest. This means if a vineyard has been exposed to smoke sometime after the point when the berries are pea size, the recommendation is to sample the vineyard two weeks prior to the harvest date and conduct a small-lot fermentation. The wine resulting from this fermentation can be subjected to sensory assessment and chemical analysis (for both volatile phenols and their glycoside precursors) in order to gauge the potential risk of any smoke taint that might arise from the smoke exposure. The AWRI’s website provides links to a range of resources on smoke taint as well as further information about the susceptibility of grape varieties. Results from a limited number of small-lot ferment samples analysed this vintage have shown that when volatile phenol results are low, glycoside precursor levels can still be above those seen in a previous study of baseline concentrations. It is therefore recommended that all analytical data (i.e. volatile phenols and their glycoside precursors) be compared with sensory results to give a true picture of any effects due to smoke.

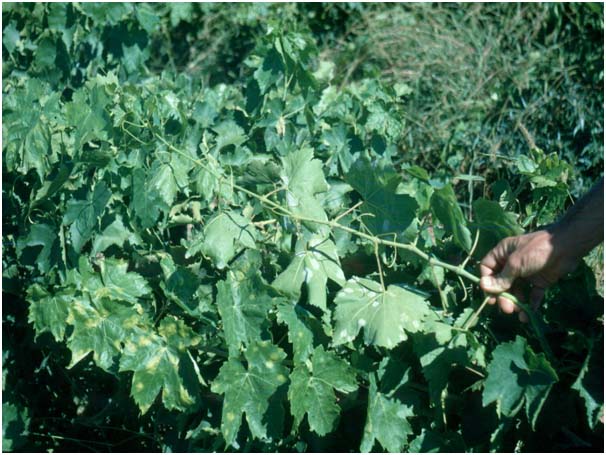

At the other end of the weather spectrum, there have been many discussions between vineyard owners and winemakers regarding the effects of the heavy rain that hit south-eastern Australia in the second week of February. If berries have split, this increases the potential for disease, including Botrytis cinerea. Wines made from Botrytis-affected grapes may contain laccase, an enzyme which is capable of causing serious oxidative damage. Testing for laccase is strongly advised. More information on managing Botrytis-affected fruit can be found in this fact sheet.

Stuck fermentations (both primary and secondary) can be a winemaker’s worst nightmare, with a number of flow-on effects including holding up fermentation vessels and compromising wine quality. In 2013 the AWRI’s helpdesk received a large volume of calls relating to these types of problems. This eBulletin is worth revisiting for its tips on how to prevent fermentation problems this vintage.

Significant interest in low alcohol yeast

Since the AWRI’s publication of a peer-reviewed article on the capacity of Metschnikowia pulcherrima AWRI1149 to produce wines with lower alcohol when used in sequential inoculation with a wine yeast strain, there has been considerable industry interest in accessing AWRI1149.

To the best of the AWRI’s knowledge, this yeast strain is not currently commercially available; however, several companies have expressed interest in commercialising it. The AWRI will be conducting its own pilot-scale trial with AWRI1149 this vintage.

One of the interesting findings of the research was that of the five strains of M. pulcherrima tested, only one was found suitable to produce lower alcohol wines via sequential inoculation. Performance in sequential inoculations was highly strain dependent. Winemakers should therefore not assume that if one strain of M. pulcherrima is commercially available that it will necessarily share the properties of AWRI1149.

To request a copy of the peer-reviewed article, please contact the AWRI’s library on infoservices@awri.com.au. For more information on sequential inoculation or to express interest in being involved in industry trials, please contact Paul Chambers on 08 8313 6600 or paul.chambers@awri.com.au.

Closure benchmarking trial set to sparkle

In 2014, AWRI Commercial Services will be conducting the world’s first large-scale benchmarking trial for sparkling wine closures. The trial will evaluate the impact of a broad range of different closure technologies on a premium bottle-fermented Chardonnay Pinot Noir, and will run for an initial 24-month period.

-

The objectives of the trial are to:

- Quantify key physical chemical and sensory impacts from each closure

- Compare the shelf-life of sparkling wine under different closures.

A group of local sparkling wine producers and a number of international closure suppliers have committed to the trial, which is expected to start in the next two months. The trial is structured to enable cost effective access to relevant results and there are multiple options available to fit producers’ technical requirements and budgets.

With the growing consumer interest in sparkling wine and the ever increasing number of closure choices available, there has never been a more important time for producers to be confident in the performance and consistency of their sparkling wine closure.

The AWRI has years of evidence demonstrating how closure selection affects the shelf-life and stylistic development of still wines, but currently there is very limited information available for sparkling wines. This trial will provide a rigorous independent assessment of closure performance to give wine producers and closure suppliers the information they need to make informed decisions for their products.

A targeted industry survey has identified the top six closures that are of most interest for Australian sparkling wine producers. These six closures form the core part of the trial and include traditional, technical and alternative closure technologies. Additional closures are also being sponsored for inclusion by closure suppliers.

The analytical testing schedule includes basic wine attributes, colour development, sulfur-containing compounds, carbon dioxide (CO2) retention, oxygen transmission rate (OTR), physical integrity and descriptive sensory analysis.

In addition, the AWRI intends to hold a number of tasting workshops in selected regions to showcase the wine’s development under the different closures. This will give small and medium wine producers the opportunity to experience the sensory impact of closure choice firsthand and will provide an overview of the trends seen throughout the trial.

If you wish to be involved in this trial or would like further information, please contact Neil Scrimgeour on 08 8313 6600 or neil.scrimgeour@awri.com.au.

Which paints cause taints?

Every vintage, the AWRI sees some wines that have been tainted by aromatic hydrocarbons from paints used on grape bins or other winery equipment. Appropriate choice of paint and sufficient curing time can go a long way towards preventing unwanted taints.

Grape bins today are typically made out of stainless-steel or high density polyethylene which can be used without the need for painting or pre-treating before use. However, bins made from non-food grade material or base steel need to be painted periodically, so they can be used in the wine industry. But which paints should you use? The paint must be suitable for contact with food, and recommended for grape bins. The main options are single pack and two pack epoxy; and both have advantages and disadvantages. It is recommended that your choice be guided by consultation with your paint supplier.

Which paints cause taints? If not applied correctly or not given enough time to dry and cure, any paint can cause a taint. Having said that, if the manufacturer’s instructions are followed for application, drying and curing time, the likelihood of a taint is significantly reduced. It is recommended that 7 to 12 days be allowed for single pack and two pack epoxy paints to fully dry and cure before use.

For more information about wine taints, please contact winemakingservices@awri.com.au.

Did you miss a webinar?

Since 2012, the AWRI has hosted more than 35 webinars on topics including: canopy management, hybrid yeast, alternatives to bentonite, rootstocks, oxygen management during winemaking and dealing with frost. If you missed a webinar when it was broadcast, you can still watch it at a time of your choice by accessing the recordings on the AWRI website. Recordings of the 2012 webinars and 2013 webinars are available. You will need to enter your name and email address for access, and you may need to download a small piece of software called a codec to allow the recordings to play on your computer. If you have any difficulties accessing the recordings, please contact Michael Downie on 08 8313 6600 or infoservices@awri.com.au.

Two new fact sheets shed light on tannin measurement

Tannin and colour measurement in grapes and wine can be challenging – and around the world different analytical methods are used. Two new fact sheets (one on grape analysis and one on wine analysis) have recently been added to the AWRI website, explaining how results from the WineCloudTM can be compared to those from other common methods.

There are a number of different methods available for the analysis of colour (anthocyanins) and phenolics in grapes. These methods all use spectroscopic techniques to measure the total anthocyanin and polyphenol content of grape homogenates. However, the extraction media used (pH and ethanol concentration) and the homogenisation processes are different for each method and therefore the extraction efficiency in each case will be different. The preparation method appears to influence all published methods for the determination of colour and phenolics in grapes.

The WineCloudTM incorporates the AWRI’s standard method (Iland et al. 2004) for the measurement of grape anthocyanins and phenolics, and a predictive algorithm based on the methyl cellulose precipitation (MCP) method developed by the AWRI (Dambergs et al. 2012) for the measurement of tannin.

Those wishing to develop a better understanding of the anthocyanin, phenolic and tannin levels in their grapes should be aware of the impact that homogenisation method and extraction medium can have in extracting these components from the grape homogenate.

For more information on tannin measurement for grapes and wine, please contact Neil Scrimgeour on 08 8313 6600 or neil.scrimgeour@awri.com.au.

References

Dambergs, R.G., Mercurio, M.D., Kassara, S., Cozzolino, D., Smith, P.A. Rapid measurement of methyl cellulose precipitable tannins using ultraviolet spectroscopy with chemometrics – application to red wine and inter-laboratory calibration transfer. Appl. Spectrosc. 66 (6): 656-664; 2012.

Iland, P., Bruer, N.; Wilkes, E., Edward, G. Anthocyanins (colour) and total phenolics of grape berries. Chemical Analysis of Grapes and Wine: Techniques and Concepts, 1st ed.; Winetitles: Broadview, Australia, 2004; pp 44.

Louisa Rose to chair the AWRI Board

Yalumba and Hill-Smith Family Vineyards Chief Winemaker Louisa Rose has been elected the fifteenth Chair of the Board of the Australian Wine Research Institute (AWRI).

Known for her work in pioneering Viognier in Australia, Louisa Rose has more than 20 years of wine industry experience and has been Chief Winemaker at Yalumba and Hill-Smith Family Vineyards since 2006. Louisa has been highly awarded for her winemaking including being named Barossa Winemaker of the Year in 1999, International Woman in Wine by the International Wine and Spirit Competition in 2004 and Winemaker of the Year by Gourmet Traveller Wine Magazine in 2008. Louisa is an experienced wine show judge, and has chaired both Perth and Hobart wine shows. She is co-chair of the South Australian Wine Industry Council and a member of the South Australian Agribusiness council.

Louisa holds a Bachelor of Science in Physics and a Bachelor of Applied Science in Oenology. During her time at Yalumba she has been a supportive industry partner for a number of AWRI research projects, particularly in the area of non-conventional yeast.

Louisa takes over from Peter Dawson who has served as a Board member since 2002 and as Chair since 2010. The AWRI Board thanked Peter for his long-standing support of the AWRI and his exceptional contributions as Board member and Chair. A farewell function was held by the Board for Peter in December 2013.

Australian Wine Industry Technical Conference update

The AWITC recently announced that the16th Australian Wine Industry Technical Conference & Trade Exhibition 2016 will be held at the Adelaide Convention Centre, from 23 to 28 July 2016.

The 16th AWITC & TE 2016 will include plenary sessions, workshops, posters, social functions and an extensive trade exhibition.

Significant support for the event has recently been confirmed from two key partners – Primary Industry and Regions SA (PIRSA) and the Adelaide Convention Centre (in association with their industry partners the South Australian Tourism Commission and the Adelaide Convention Bureau).

For more information about the 2016 event, please contact Kate Beames, Conference Manager, on 08 8313 6600 or kate.beames@awitc.com.au.

2006-2013 Final Report available online

At the conclusion of the AWRI’s 2006-2013 investment agreement with the GWRDC, AWRI staff prepared a detailed report of the key outcomes from that 7-year period. This report is now available from the AWRI website.

The report is divided into 13 streams plus an Impact Summary and includes a full list of publications from the investment period.

The outcomes achieved for industry during the period reflect the success of the investment model that was in place – one that combined long-term stability with short-term adaptability and allowed the AWRI to pursue medium-term research and development projects while responding to changing industry conditions.

Recent literature

John Fornachon Memorial Library at the AWRI delivers journal articles and loans books to Australian grapegrowers and winemakers. Books can be searched and requested via the Library catalogue – or you can email the Library with your request. A list of recent AWRI publications follows.

- To order AWRI staff publications and articles from Technical Review please contact the Library

- Articles and books on specific topics can be searched for and ordered via the Library catalogue

- To request a Literature search on a specific topic contact the Library via email or telephone 08 8313 6600.

Recent AWRI staff publications

1583 Contreras, A., Hidalgo, C., Henschke, P.A., Chambers, P.J., Curtin, C., Varela, C. Evaluation of non-Saccharomyces yeast for the reduction of alcohol content in wine. Appl. Environ. Microbiol. doi:10.1128/AEM.03780-13; 2013.

1584 Viviers, M.Z., Smith, M.E., Wilkes, E., Smith, P.A. Effects of metals on the evolution of volatile sulfur compounds in wine during bottle storage. Aust. N.Z. Grapegrower Winemaker (600): 49-51; 2014.

1585 Wilkes, E. You’ve got to be a hot shot to hit the moving target of cold stability. Aust. N.Z. Grapegrower Winemaker (600): 43-46; 2014.

1586 Cowey, G. Ask the AWRI: Top tips for a successful yeast culture. Aust. N.Z. Grapegrower Winemaker (600): p. 42; 2014.

1587 Bindon, K.A., Madani, S.H., Pendleton, P., Smith, P.A., Kennedy, J.A. Factors affecting skin tannin extractability in ripening grapes. J. Agric. Food Chem. doi.org/10.1021/jf4050606: 12 p.; 2014.

1588 Dry, P. Malvasia istriana. Wine Viti. J. 29 (1): p. 53; 2014.

1589 Viviers, M., Smith, M., Wilkes, E., Smith, P., Johnson, D. The role of trace metals in wine ‘reduction’. Wine Viti. J. 29 (1): 38-40; 2014.

1590 Francis, L. Des études multidisciplinaires à l’Australian Wine Research Institute. Revue des Oenologues et des Techniques Vitivinicoles et Oenologiques (149 Supp.): p. 9; 2013.

1591 Geffroy, O., Dufourcq, T. Carcenac, D., Siebert, T., Herderich, M. Nouvelles acquisitions sur le caractère poivré. Des vins rouges de Duras de l’AOP Gaillac. Revue des Oenologues et des Techniques Vitivinicoles et Oenologiques (149 Supp.): 49-51; 2013.

1592 Bartowsky, E., Costello, P., Krieger-Weber, S., Silvano, A., Dumont, A., Francis, L., Travis, B. Au-delà de la fermentation malolactique. Évaluation et caracterisation de l’impact sensorial des bactéries oenologiques sur le caractère fruité des vins rouges. Revue des Oenologues et des Techniques Vitivinicoles et Oenologiques (149 Supp.): 61-65; 2013.

1593 Essling, M. Ask the AWRI: Canopy damage from herbicides. Aust. N.Z. Grapegrower Winemaker (601): p. 32; 2014.

1594 Dry, P. Terroir and the topic of wine typicity. Aust. N.Z. Grapegrower Winemaker (601): p. 40; 2014.

1595 McRae, J., Smith, P. Seal the deal on pH, red wine colour and tannin during bottle ageing. Aust. N.Z. Grapegrower Winemaker (601): 51-54; 2014.

1596 Gawel, R., Schulkin, A., Smith, P.A., Waters, E.J. Taste and textural characters of mixtures of caftaric acid and Grape Reaction Product in model wine. Aust. J. Grape Wine Res. 20 (1): 25-30; 2014.